With a small amount of external circuitry it can also control

external devices

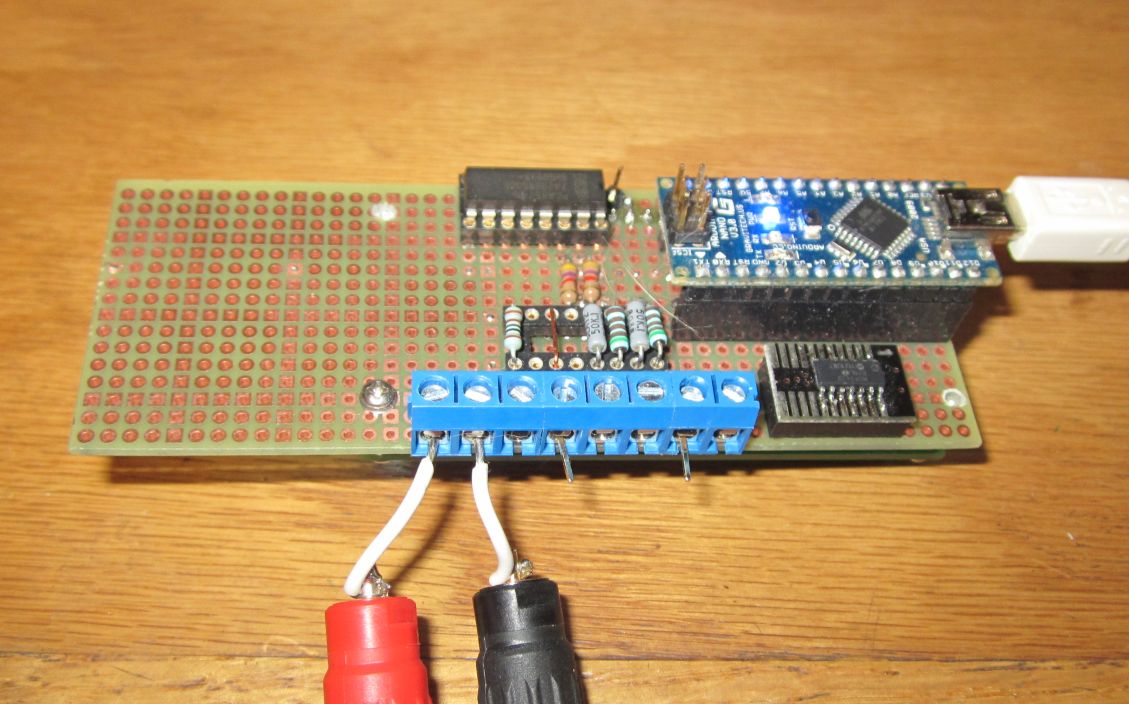

The top view. The area to the right is for optional controls

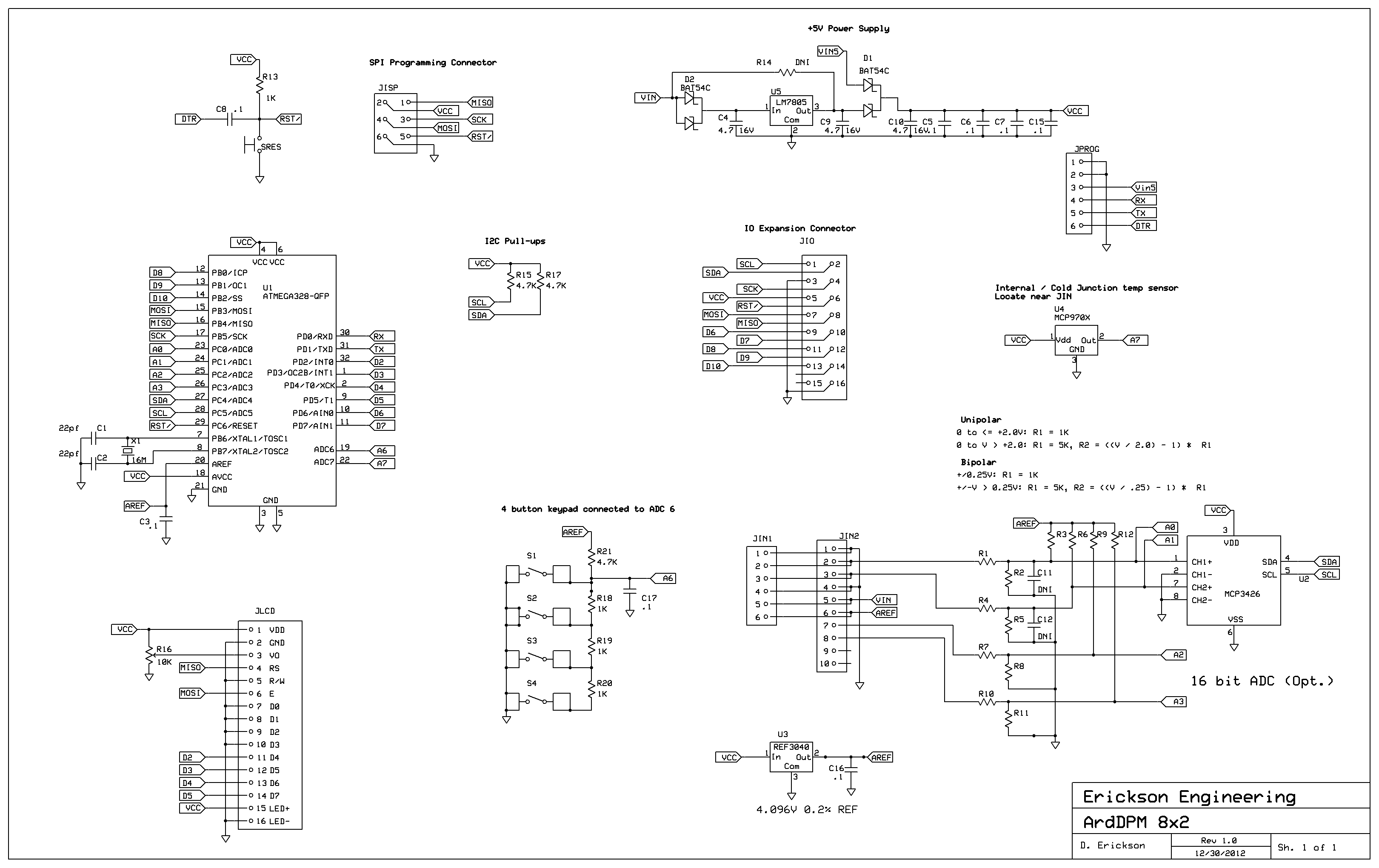

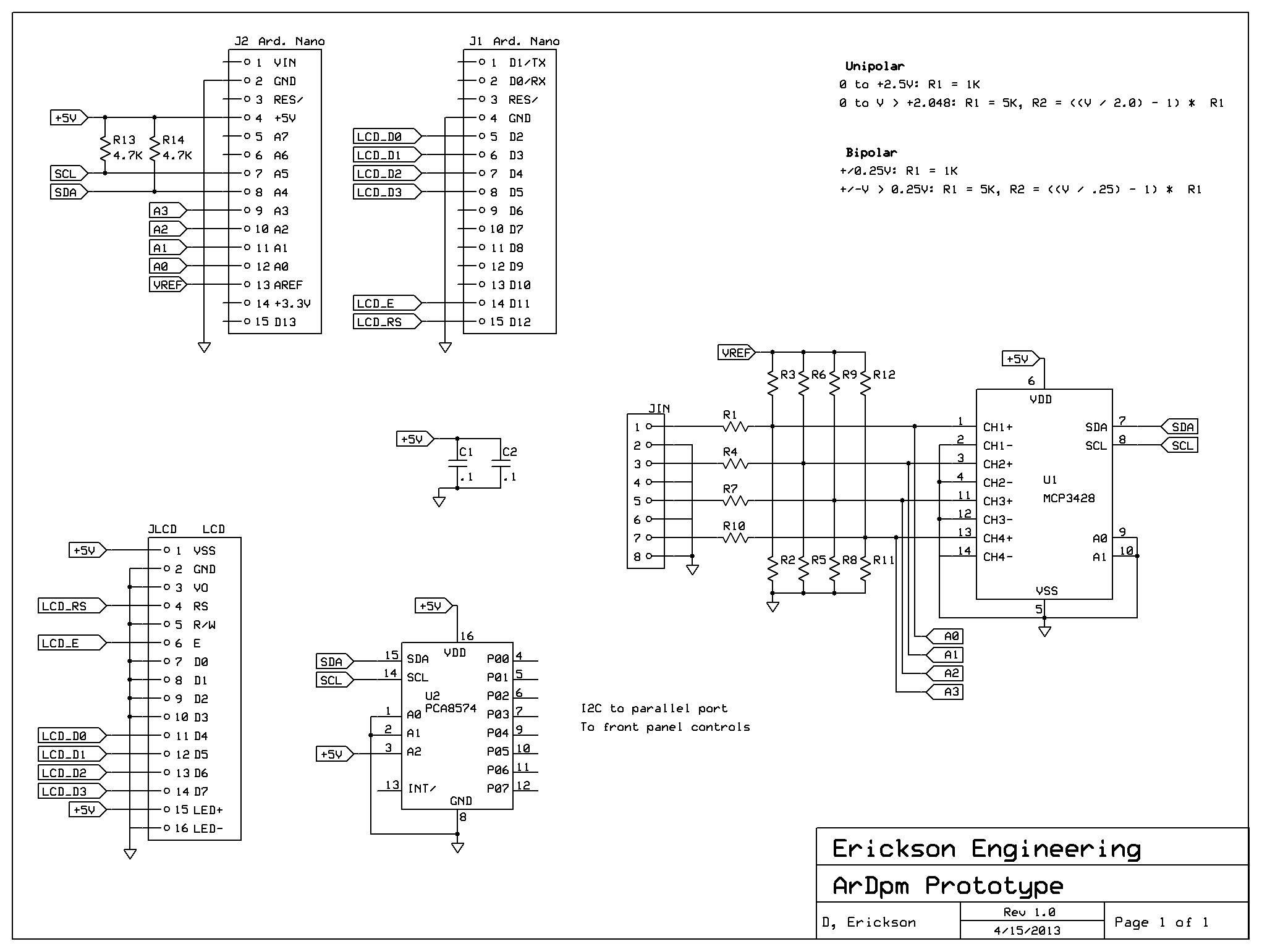

I chose to use an Arduino compatible processor. This made the

development and tools free and simple. The basic libraries for

controlling an LCD, ADC, I2C and other peripherals are there and

easy to use. The bare ATMEGA328 processor is about $1.50 in 100's

and can directly do 10 bit conversion, suitable for some

applications. I usually include provisions for a precision

voltage reference connected to the processor reference pins. This

allows any reference voltage up to about 4.5V to be used. Common

reference values are 2.00, 2.048. 2.5, and 4.096V.

But many of my application need more than 1024 counts of ADC.

After investigating low cost ADCs I found a very nice one: the

Microchip MCP34xx series of Delta-Sigma ADCs. These are available

in either 16 or 18 bits, have flexible differential inputs, I2C

interface, and an internal reference. They come in 1 to 4

input versions. They are relatively slow, but plenty fast for a

panel meter read by a human. And they can trade-off resolution vs.

conversion time. The 2 channel, 8 pin, MCP3426 is $2 qty 100.

I tested the 4 channel 16 bit part, the MCP3428 and was very

pleased with the linearity, noise level, input ranges, and easy to

use I2C interface. RMS noise was well under one count. But what

got me excited was the 8x range. This range measures +/- 256mV

full scale. Since the input voltage can be negative and as low as

-.3V, the part can measure negative voltages up to full scale,

with only a positive power supply. This is ideal for a Digital

panel meter!

The input impedance for the 8x range is 2Meg / 8 = 250K ohms, so

it will cause a slight load on a 1-5K source impedance, But this

can be calibrated out. In a digital panel meter, resistor dividers

are often used to convert a higher input voltage to the ADC input

voltage. This approach allows the full resolution of the ADC to be

used to measure any input voltage range. So for example if you

want to measure 40V, the divider is 40V / 256V = 156.25 : 1.

Assuming a 5K resistor to ground, the top resistor is (156.25 -1)

* 5K = 776K. The total input impedance is 777K + 5K = 781K. It is

good to leave some extra input range to account for component

errors and for calibration if you want, so let's use standard

values of 4.99K and 806K for our 40V application. At 40V this

draws only 50uA from the load, suitable for higher power battery

applications.

Calibration and Accuracy

The MCP34xx parts have a good internal reference: .1% and 15ppm/ºC

gain error including the PGA and the reference. Their offset

performance is excellent: 30uV typ. and 50nV/ºC, This is due to

their auto-zero architecture. This means that for many

applications, no offset calibration will be needed. To get better

than .1% gain accuracy or to compensate for the input divider

resistor errors, you will want to do a simple gain correction.

One nice thing about Arduinos is that it is easy to make unique

code changes for a single unit. All you need is to change a FLOAT

constant, recompile, and download. This is a bit of a hack

since you are modifying the source code for each unit, but it

eliminates the need to write calibration code and manage EEPROM

values. You can do it with the built-in EEPROM, particularly if

you want to calibrate the system after installation.

Can it measure thermocouples??

Yes it can. A K-type thermocouple is about 40uV / ºC. One

count of the 16 bit ADC at the 8x range is 0.256v / 32768 = 7.8uV,

so about 0.2ºC resolution. Cool! A thermocouple needs

cold-junction compensation, but a solid-state temp sensor

connected to a spare 10 bit ADC channel on the processor can do

the job nicely. I used an MCP7900. For the thermocouple, if

you want more temperature resolution, the 18 bit MCP34xx parts can

be used.

This means that the panel meter can be the basis for a reasonable

temperature controller for an environmental chamber or IR reflow

(toaster) oven. Or any other application requiring temperatures

over 100ºC.

Display

My first prototype used a 16x2 row LCD. I found it was a bit

large for my projects. And 16 characters can be too many for just

displaying 4.5 digits of voltages or currents. A standard

16x2 LCD is 3.15" long. There are 8x2 LCDs that are either 1.58"

(40mm) or 2.3" (58mm) wide. 8 characters is enough to display 5

digits, sign, decimal point and units, ie. -2.3456V I

chose the 56mm versions.

A downside of using alphanumeric displays

is that the digit size can be small. You can read it from a

viewing distance of a few feet, but probably not from across

the room.

Another downside is that for a compact

design, the PC board typically driven by the display size.

This isn't much of a problem if you can find a 'standard' size

LCD. Be careful here since there can be small

manufacturer-to-manufacturer variations.

LCD Connector

Alphanumeric LCDs come without connectors. Soldering one to a

PC board is pretty simple: use a 2 row 14 pin header and solder it

to both the display and the PCB. But this means that you can never

have access to the PC board rear side behind the LCD. Since I want

a flexible platform, this would limit expansion. I looked at

various 2 row .1" thru-hole header, and most are pretty tall. My

solution s to use low-profile female pins that allow the male pins

to protrude below the surface of a board, such as Harwin H3153

(Mouser) and MillMax

0552 (Digikey). These accept 0.018" or 0.020" diameter pins,

also made by Harwin and MilMax. These allow about .15"

board-to-board spacing for about $0.18 a pin pair. If you decide

you no longer need the ability to remove the LCD, simply use a low

cost 2 pin header. If height is no object, use any .1" pins socket

combination.

The 58mm LCDs are typically 14 pins, with 2 pins at the opposite

end for the LED back-light. My idea here is to install a 16 pin

header in the 14 pin location, but cut the 2 extra pins off where

they plug into the LCD. Then run 2 wires along the back of the LCD

to pins 15 and 16 of the header to the back-light pins. The

board will therefore support both 14 and modified 16 pin LCDs.

You could of course add a second connector between the LCD

back-light pins and the board, but this seems cumbersome.